Three hygiene zones

Selecting the right components is crucial for the safety and the correct functioning of the production line. Industrial work groups such as the “Safe Food Factory” in Benelux, have compiled recommendations for hygiene requirements that address each area of the production line. All components must comply with strict hygiene standards – which become even more stringent when the components come into contact with food.

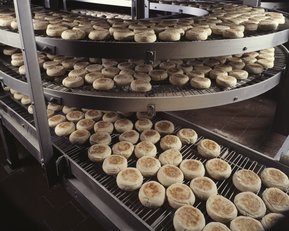

1. Hygienic Design Zone

These are areas where equipment regularly and predictably comes in contact with food as it being produced. Food conveyors, mixers, nozzles and cooking surfaces are examples of Hygienic Design environments. Bringing electrification to these zones brings a unique challenge as it represents the highest probability of product contamination if a pathogen were present on the equipment. Cables and connectors are frequently needed in this zone for sensing applications.

2. Splash Zone

These areas immediately surround the food production zone; dripping product or run off from equipment can cause product contamination. This zone is regularly cleaned as part of any plant Hygiene Plan. Cables, connectors and conduits used in this area need to withstand harsh cleaning processes and be designed in a way that is consistent with good sanitary food design machine practices, eliminating areas where moisture and debris can collect.

3. Non-Product Zone

These include all areas and facilities in a factory which do not come into direct contact with the foodstuffs. However, these areas are often cleaned together with the more sensitive areas, which in turn may result in high chemical and mechanical stresses.

LAPP products are tested with the three hygiene zones in mind. Food manufacturers can rely on a trusted range of hygienically designed products to install on all areas of the production line.